SHOP DRAWINGS: EVERYTHING YOU NEED TO KNOW FOR FURNITURE MANUFACTURING

Shop drawings are precise, detailed illustrations that transform design concepts into technical plans for manufacturing and construction. They serve as a bridge between a creative vision and production. The drawings provide manufacturers, fabricators, and installers with specifications like dimensions, materials, hardware, and assembly details. By offering a visual and technical representation of a project, such drafts help get rid of ambiguities, prevent costly errors, and streamline production.

In the furniture manufacturing industry, shop drawings play a crucial role in establishing a clear workflow. They improve collaboration, enhance quality control, and optimize resources. In this guide, our CAD drafting studio will explore what shop drawings are, why they matter, their key components, and the processes involved. Read on to learn more!

Overview of Shop Drawings

What are Shop Drawings?

Shop drawings are technical documents that provide a detailed representation of how a component or structure should be fabricated and assembled. They focus on specifics and offer clarity for manufacturers. In furniture manufacturing, such drawings ensure that every piece is built to exact specifications. Precision in technical drawings eliminates misunderstandings and errors. By providing exact details, these drawings align all stakeholders with the original design vision.

Key Elements of Shop Drawings

Accurate dimensions, measurements, and scaling are crucial in ensuring components fit perfectly during assembly. These are vital for maintaining the structure and functionality of an item. Shop drawings also specify materials, finishes, and textures to ensure adherence to design intent. This information helps manufacturers procure the right materials and maintain quality. Clear diagrams show how parts are joined, which ensures proper assembly and durability of the final product.

Why are Shop Drawings Important?

Enhanced Accuracy

Furniture shop drawings act as a reliable reference, reducing the likelihood of errors. With clear instructions, manufacturers and contractors can avoid rework and delays. This ultimately saves time and costs. By serving as a shared resource, shop drafts ensure designers, engineers, and contractors work towards the same objectives. This fosters better coordination and smoother project execution.

Compliance and Approval

Shop drawings ensure compliance with building codes, safety regulations, and industry standards, helping to avoid legal or structural complications. These drawings are reviewed and approved by stakeholders to confirm design intent is feasible and aligns with project requirements.

Want to know more about CAD services our studio provides? Check out this archive with projects examples and learn more.

Types of shop drawings

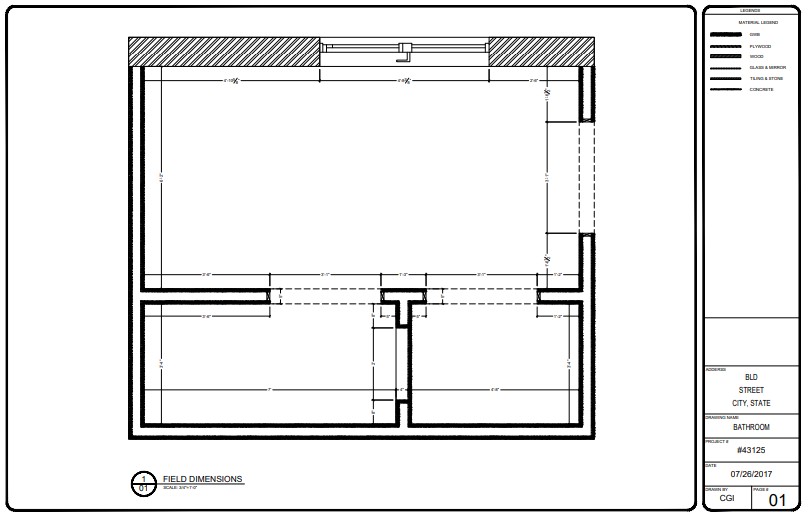

Field Dimensions

Field dimensions are essential for capturing precise room measurements to ensure furniture or fixtures fit perfectly within available space. These drawings include details such as room size, wall thickness, door niche depth, and construction materials. They are particularly useful when designing furniture for tight spaces like kitchens or bathrooms.

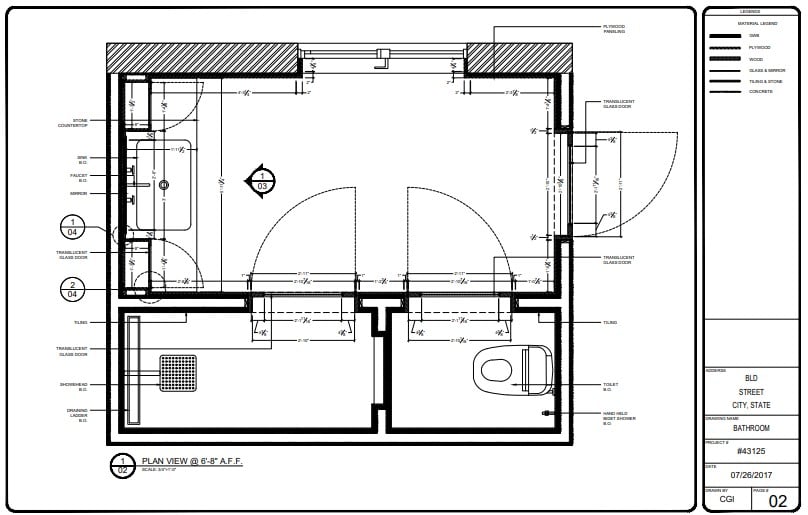

Plan View

Plan views provide a bird’s-eye-view perspective of the layout, illustrating the placement of all objects within a room. These drawings emphasize dimensions, furniture positioning, materials, and appliance names. This ensures correct integration during manufacturing and installation.

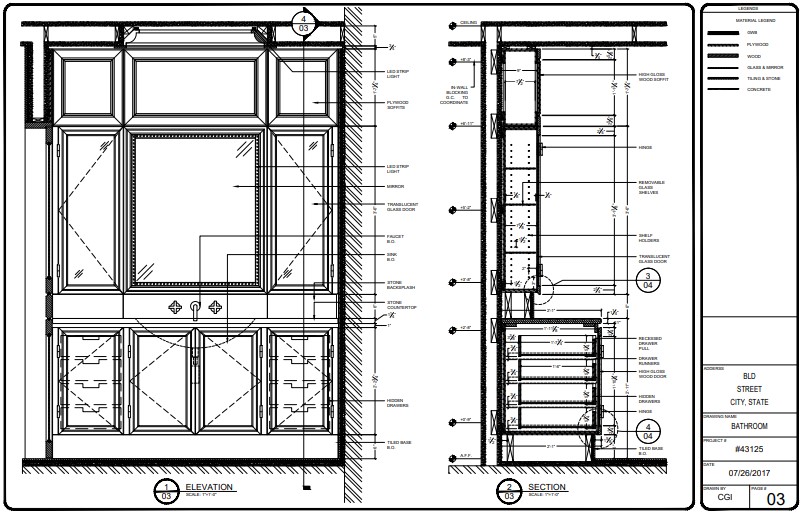

Elevation Drawings

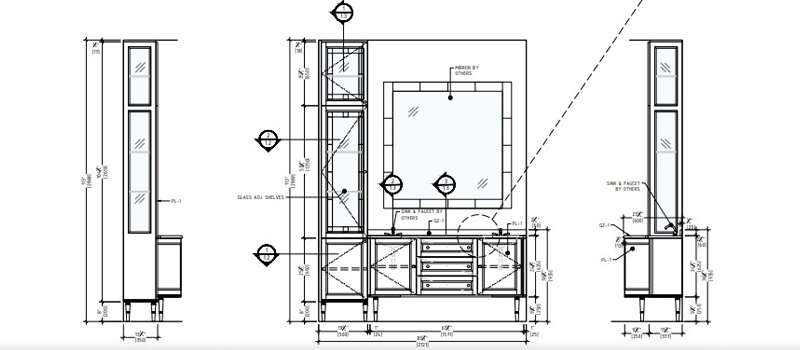

Elevations offer detailed views of objects from the front, left, or right angles. They showcase exact dimensions and materials, including scaled drawings with both general and specific measurements. Labels for individual components further aid in accurate construction.

Plan Section

Plan sections break down objects into various segments. A section reveals construction details from a different angle. These drawings highlight vertical and horizontal cuts, focusing on components such as drawers, shelves, or cabinets, ensuring every element is clearly understood.

Detail Drawings

Detail drawings concentrate on the smallest components, such as mounts, sliding gears, or decorative legs. Enlarged and intricate views in these drawings ensure precision when constructing complex elements.

The Shop Drawing Process

Preparation

Creating shop drawings begins with collecting info from designers and engineers. It includes base drawings, precise measurements, and specifications that outline the design intent. Advanced tools such as CAD (Computer-Aided Design) and BIM (Building Information Modeling) software are used to transform the data into detailed, scalable, and editable drawings. CAD software enables precision in 2D and 3D modeling. Meanwhile, BIM adds depth by integrating data on materials and building processes. This phase ensures that the shop drawings reflect the original design vision while taking technical and material constraints into account.

Review and Approval

Once the shop drawings are prepared, they undergo a meticulous review process. This step ensures that drawings align with the project’s specifications and adhere to regulatory standards. Key stakeholders, including project managers, engineers, and clients, collaborate to evaluate them. The goal is to identify and address any potential discrepancies early, ensuring that the drawings are ready for execution. Effective review processes rely on clear communication and a structured timeline.

Production and Execution

Shop drawings serve as manufacturing blueprints. These are the translations of the design into instructions for production teams. The drawings guide every aspect of fabrication from material selection to assembly. This ensures that the finished product matches the intended design. Additionally, shop drawings are dynamic documents—any changes in site conditions, client preferences, or regulations are reflected in updated versions. This adaptability minimizes errors and keeps the project on track.

Best Practices for Shop Drawings

Focus on Clarity

Clear communication is essential in shop drawings, as it directly impacts the accuracy and efficiency of the manufacturing process. To achieve this, drawings should include detailed annotations, such as labels, legends, and notes. Visual elements, such as color coding and standardized symbols further improve readability, reducing the chances of misinterpretation. By prioritizing clarity, stakeholders can confidently reference the drawings without confusion.

Use of Advanced Tools

Leveraging advanced tools software tools is vital for the efficient creation of shop drawings. CAD software offers accuracy in drafting, while BIM incorporates data on construction materials, processes, and performance. These tools streamline collaboration, allowing teams to share and update drawings in real time. Furthermore, their integration with project management systems ensures that changes are tracked and communicated effectively. Such an approach maintains alignment across all professionals involved in the project.

Regular Communication

Consistent and open communication across all project participants is the cornerstone for successful shop drawing implementation. Regular offline or virtual meetings provide opportunities to discuss progress, address concerns, and incorporate feedback. Such proactive communication minimizes errors and fosters a cohesive workflow, contributing to the project’s success.

Common Challenges in Shop Drawings

Errors in Initial Design

Errors originating from flawed initial designs can carry over to shop drawings, leading to costly delays and reworks. For example, a miscalculation in the dimensions of a preliminary sketch can result in furniture pieces that do not fit the intended space. To mitigate this issue, it is critical to validate all original designs before initiating the shop drawing process. Employing CAD tools at this stage and conducting thorough reviews are proven strategies to identify and fix errors before they escalate.

Approval Delays

Timely approval of shop drawings is crucial for maintaining project schedules and budgets. Delays often occur when stakeholders, such as clients or project managers, take longer than anticipated to review the drawings. These setbacks can ripple through production timelines. Implementing structured review schedules, automated reminders, and milestone-based tracking can streamline the approval process.

Lack of Coordination Between Teams

Furniture manufacturing projects often involve multiple teams, including architects, engineers, and manufacturers, each working on interconnected tasks. A lack of coordination among these teams can lead to inconsistent or conflicting shop drawings. To prevent this, it is essential to use centralized collaboration platforms, such as the CRM system at our company. Such tools provide real-time access to shop drawings, and facilitate communication and version control, ensuring the project’s successful completion.

Properly created shop drawings are the foundation of successful furniture manufacturing. These technical documents save time and resources by ensuring precision, efficiency, and collaboration among all parties. They enable seamless communication between designers, engineers, and manufacturers, reducing the likelihood of costly errors and delays. With professional shop drawings, projects achieve higher quality standards and ensure client satisfaction.

Wonder how much high-quality drafting services cost? Check out the examples of our real projects with pricing.

Want to create millwork items precisely and effectively? Use ArchiCGI drafting services and get detailed high-quality shop drawings for your projects.

I have been surfing on-line greater than 3 hours today, yet I by no means found any interesting article like yours. It is lovely worth enough for me. In my view, if all site owners and bloggers made just right content material as you did, the web will likely be much more helpful than ever before.

Thank you for informative post