REVIT FOR MILLWORK: HOW TO REDUCE THE PROJECT COST

Revit for millwork projects is an excellent for cutting budget on both design development and the manufacturing itself. This type of BIM helps to calculate the right amount of materials for a product, therefore thoroughly minimize wastings, as well as to detect errors at the early stages of the process.

A millwork company has been working exclusively with shop drawings from the launch of the business but it has brought too many problems. Even the smallest inaccuracies of the drafts led to incorrect calculations of the amount of material needed for the manufacturing process. Often millwork specialists ordered too much or not enough resources which caused conflicts with clients and unpredicted expenses. Moreover, the flaws of millwork prototypes based on drafts always cost too much money as Manufacturers have to redo them again and again until Designers finally approve the design. As a result, the whole process is too expensive, and that’s why millwork specialists want to find an alternative way.

CAD modeling services can be the ultimate solution to all these problems. It allows to calculate the budget as accurately as possible and find all product flaws before the manufacturing stage. Learn how Revit BIM can help Manufacturers to cut the cost of millwork projects without losing the quality of the result.

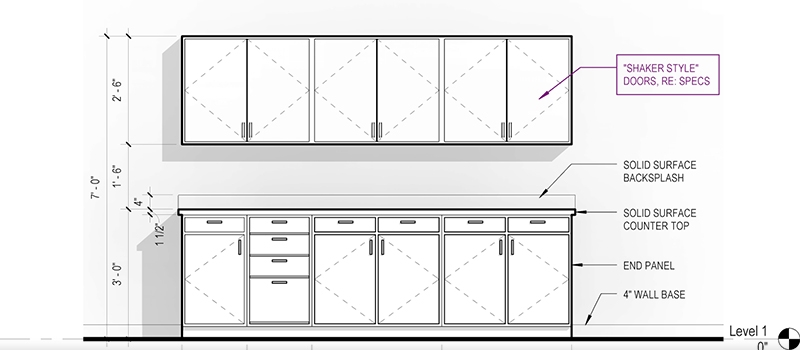

#1. Use the Database of Revit 3D Models

Most of the big 3D studios that provide Revit modeling services have their own database of ready-made CG elements for different kinds of projects. Thanks to it, millwork specialists can find suitable templates for their Revit models and require to use them as the basis for the ordered 3D objects. Revit BIM Artists are able to adjust previously used templates to similar projects and only then complete millwork 3D product with some new elements. In this way, Revit millwork BIM is a cost-saving alternative to more expensive fully custom 3D models.

#2. Download Free Revit Families Details

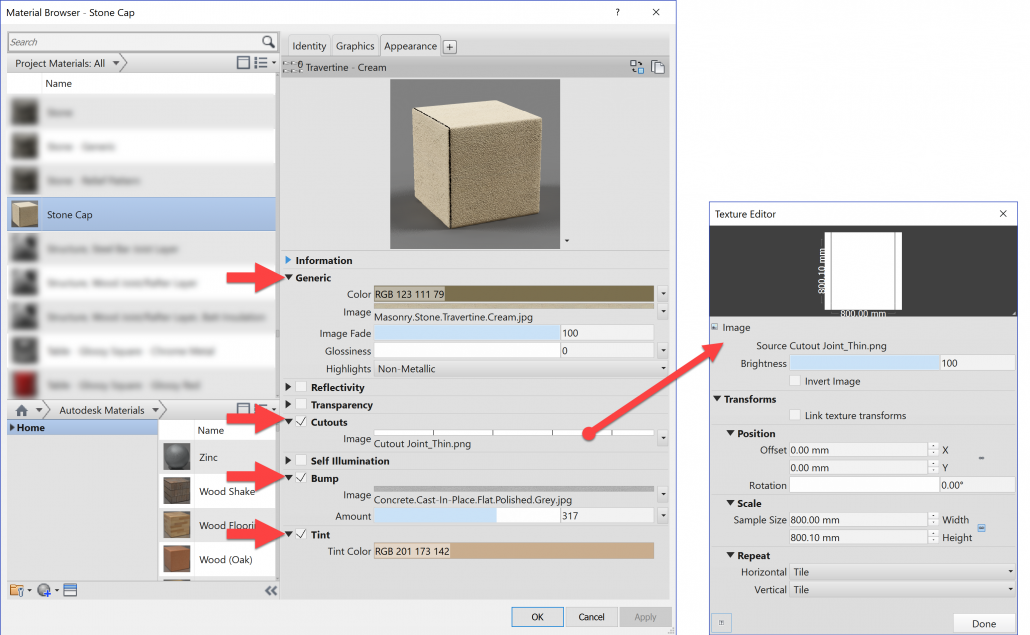

Another way to reduce the budget for a Revit millwork project is to download the necessary BIM parts and details from the specific websites for free. Such basic elements of Revit 3D models are also called families – they could be the already completed objects or only parts of them. Revit families details can be used as the foundation even for custom products with minor modifications and adjustments. In this case, the total price of a millwork project will be more cost-saving than creating a new 3D model from scratch.

Want to know more about CAD services our studio provides? Check out this archive with projects examples and learn more.

#3. Calculate the Amount of Materials

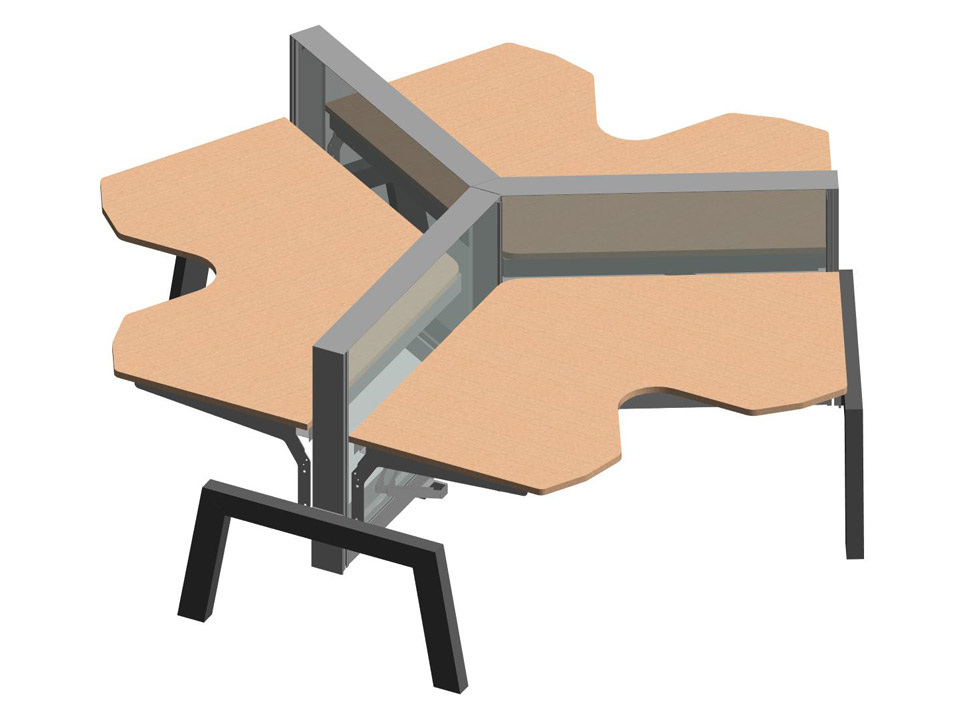

One of the main advantages of Revit millwork modeling for the whole manufacturing process is the function to accurately calculate the necessary amount of materials in advance. Revit software automatically gives the information on how much resources a millwork specialist needs for each part of a product based on the technical data of a BIM model. This feature allows Manufacturers to purchase the exact amount of materials even before the start of the production stage and avoid unnecessary waste or shortcoming in the future.

#4. Detect Flaws Before Manufacturing

Revit millwork modeling is an effective way to detect and fix all the technical problems of a product before the start of its manufacturing. This function allows finding the disadvantages of geometry, aerodynamics, parameters, and other specifications of a millwork object. Moreover, Revit can help to check if a product meets all required manufacturing standards according to a Designer’s demands. The early identification of such errors at the design development stage will reduce the cost for possible corrections during the production process.

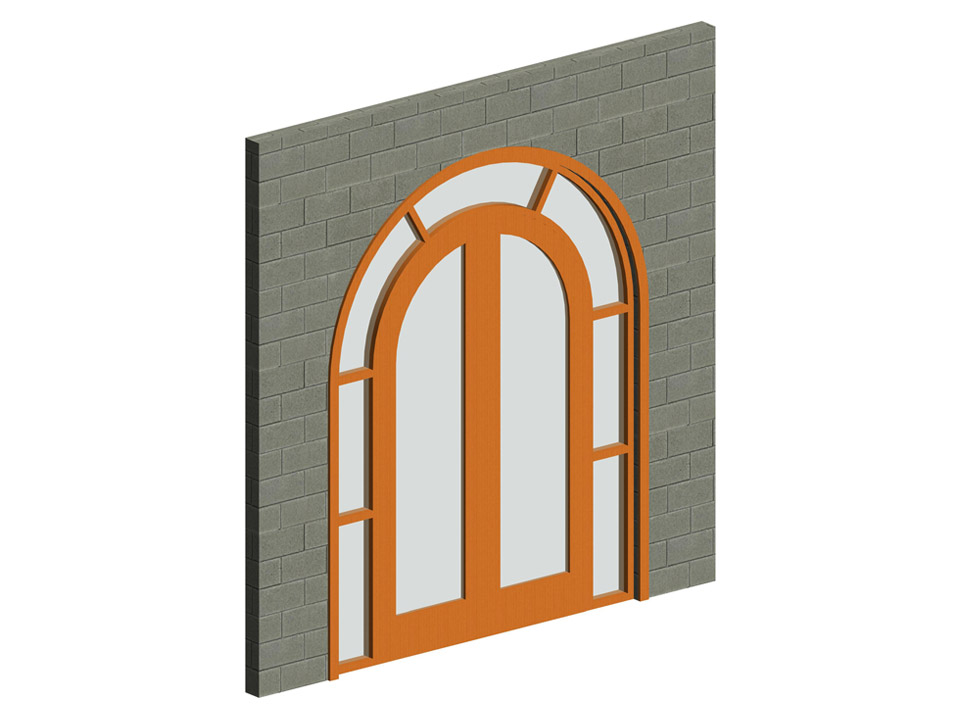

#5. Test Millwork Design Before Product Launch

A more traditional way to test the design of a millwork object and get the approval from a Designer is making a prototype. However, it’s not the most budget-friendly option. First of all, its creation costs almost as much as the finished product, and secondly, in the case of corrections from the Designer, millwork specialists have to redo it. The longer the process of fixing flaws of a prototype takes, the more money is wasted.

Realistic Revit millwork models with all the textures and details can replace the costly prototyping process completely. All Manufacturers have to do is to show their clients a 3D version of millwork design and get the approval from the start. Later, the successful product manufacturing can be achieved on the first try.

Using Revit for millwork modeling projects is a fast and effective way to accelerate the manufacturing process and minimize the cost at the same time. BIM models will help to make the design development more budget-friendly at the expense of ready Revit families and templates. In addition, despite it being a cost-saving solution, Revit millwork modeling help to keep product quality on the high level by detecting flaws and technical problems at the early stages of the process.

Wonder how much high-quality drafting services cost? Check out the examples of our real projects with pricing.

Want to make the design development and production of millwork objects more cost-saving? Use Revit modeling services and calculate the budget for your project as accurately as possible.

Leave a Reply

Want to join the discussion?Feel free to contribute!